A ring as unique as you.

Design your own custom jewelry

At Earth’s Treasury, we absolutely love working with our clients to make their custom jewelry vision come true, whether it’s just “your version” of a classic style, or something totally unique like this ring below. Follow along and see how one client’s vision was taken from idea to finished ring (or in this case, rings). You can also click on the image below to see a short video

1. Select your stones

Our client had a vision of a ring that captured the green of the forests where she grew up. She had selected the green Montana Sapphire center stone because Montana had a special meaning in her relationship, and the green color reminded her of the forests of the Pacific Northwest. She also wanted to integrate yellow hues to capture the feeling of the mixed forest of conifers and deciduous trees in the autumn. Based on these ideas, our jewelry designer Lauryn came up with a concept for a vine-like ring set incorporating all Montana sapphires, and then started the process by selecting a suite of stones that combined the yellow and green hues our client loved.

2. Show us your idea

Once she had selected all of the stones, Lauryn created a series of sketches to solidify the idea with the client. When she had agreed to the concept, Lauryn created a small watercolor rendering of what the final ring would look like.

While we only do this for special commissions, we often will do basic pencil sketches as part of the regular design process.

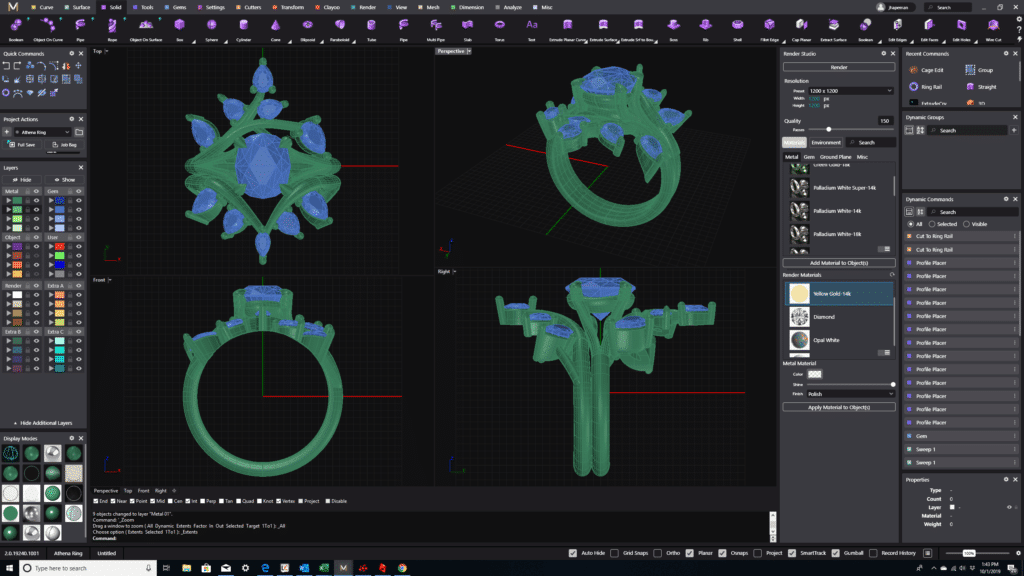

3. Computerized CAD modeling

Our client was delighted with the watercolor, so we moved on to the next step: creating a computerized CAD model of the ring. This is the most complicated process for us internally, especially for a complex shape like this, but it also allows us to create a ring that is precisely matched to your gemstone, ensuring a perfect fit.

4. 3D model rendering

Once the CAD model is made, we create a 3D computer rendering to give a better impression of what the finished ring will look like in person. While not perfect, it’s much more life-like than a sketch or painting. This is also the time where any small adjustments to the design can be made.

5. 3D printed prototype

Once the CAD model is made, we create a 3D computer rendering to give a better impression of what the finished ring will look like in person. While not perfect, it’s much more life-like than a sketch or painting. This is also the time where any small adjustments to the design can be made.

6. High resolution 3D print

If everything fits as expected, the next step is to print the ring in a special castable wax or resin, depending on the project. This version is printed at an extremely high resolution so that every detail can be faithfully reproduced.

The model is then sent to a specialty casting house, to ensure that we get the very best product possible.

This particular ring was cast in platinum, but we have a wide variety of precious metals you can choose from.

7. Finishing touches

After many hours of careful finishing work, the matched rings are finally complete. To retain an organic look for this pair of rings, we left portions of the “branches” of the vines unpolished or only lightly polished, to give them a textural feel. As you can see, the final product is faithful to the original watercolor sketch and the 3D rendering.

The client?

She was ecstatic-scroll down for the image she sent and her testimonial.

It wasn’t the surprise proposal I was expecting, and because I had always assumed my someone would be picking the ring, I guess I hadn’t spent much time thinking about the possibilities, and it showed. To start, I pitched a concept very faithful to a traditional engagement ring design, but my heart wasn’t in it. I think Lauryn sensed that; she encouraged me to be as imaginative as I wanted and stuck with me through some wildly-evolving iterations of inspiration, offering limitless patience and enthusiasm all the while.

The result has been an enchantingly unique ring (set) people have fallen all over themselves to get a closer look at. We finally made this thing “Facebook-official” over the weekend, and people were as interested in the ring as they were the reason I’m wearing it. In fact, about a third of the comments didn’t even offer congratulations, just, “OMG, that ring though…” Must say, I’ve never seen a diamond get a reception like that, but I digress.

Thanks for making it such a great experience. I’ll be back.

– Athena

Are you interested in making a custom ring?

We’ll be glad to help.

Meanwhile, you can head over to our gemstone listings and find the perfect gem for your ring.